Plastic Pipe Testing Equipment

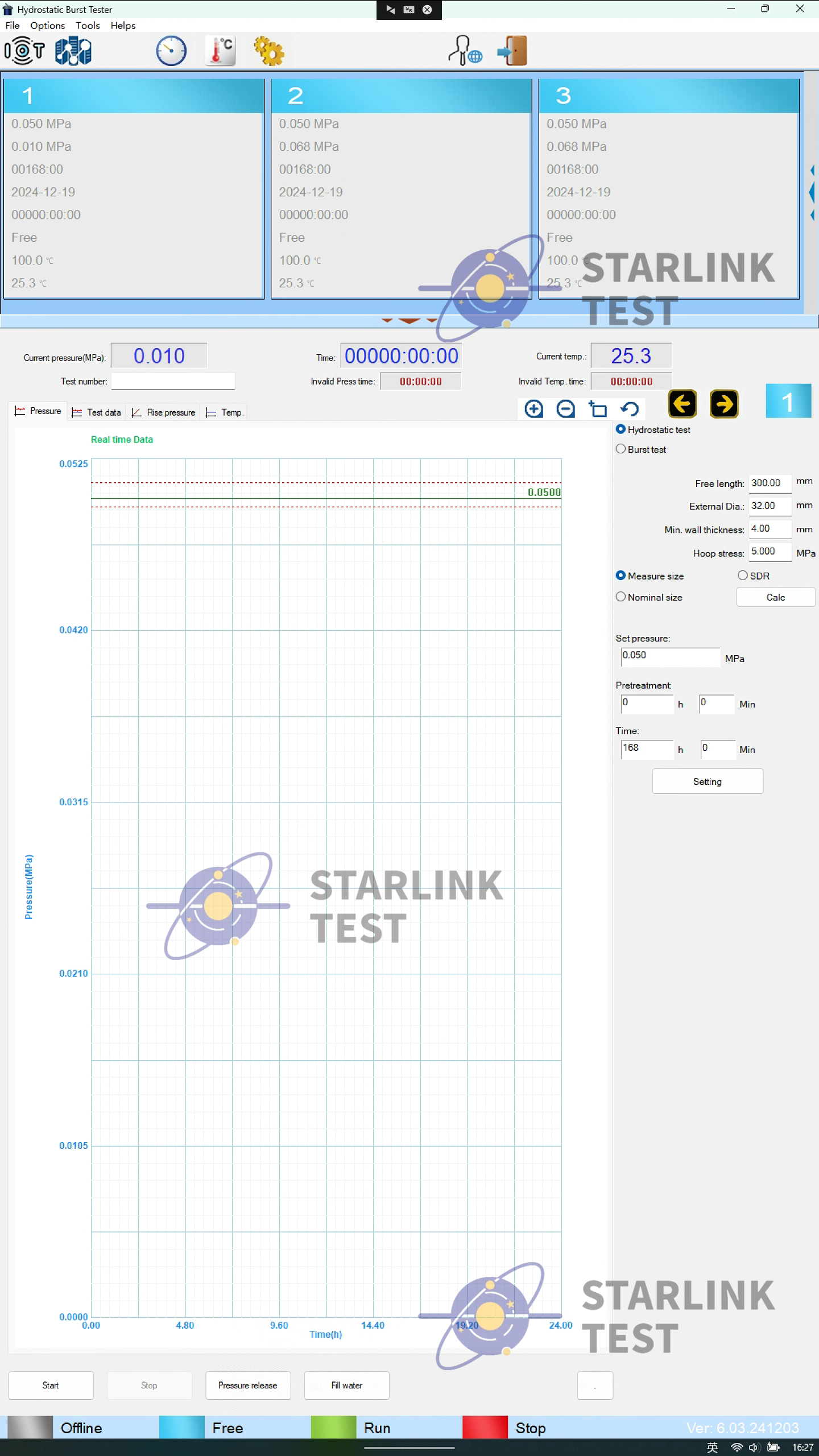

Hydrostatic Pressure Tester

Pressure Control System

Model: SL-HY0XX

The SL-HY0XX is designed to determine the resistance of thermoplastic pipes under constant internal water pressure and temperature.

Standards:

ISO 1167, ASTM D1598, ASTM D1599

Key Features:

1.Modular Design with Integrated PC Controller:

The hydraulic tester features a built-in PC controller and a modular structure. Each module (5 stations) is equipped with a separate microcomputer for command reception from the PC, pressure control, and data collection. It provides continuous feedback to the PC via a serial bus. The system intelligently determines the sample size and material, offering optimal pressure increase algorithms. It is capable of rapid pressure growth for pipes with high expansion rates, maintaining stability at constant temperatures. The PC collects test data, analyzes leakage or burst results, and includes sample conditioning, real-time monitoring, data storage, power failure data protection (memory), and recovery upon power restoration.

2.User -Friendly 32-Inch Industrial Tablet Control:

The unique control interface features a 32-inch vertical display, showing the operational status of 30 workstations (pressure, temperature) simultaneously on a single screen, facilitating easy operation.

3.Convenient Setup:

The stand connects to the bath using high-pressure hoses and quick-release couplings, ensuring easy installation.

4.Stable Pressure Control:

The system employs a branded electromagnetic valve that is resistant to clogging and has a long service life. A three-level pressure control system consists of a pressure station, accumulator, and microcomputer, providing precise pressure regulation.

5.Sample Conditioning and Automatic Test Initiation:

The system includes sample conditioning features and automatically initiates tests following conditioning.

6.Automatic Temperature Monitoring:

It automatically collects the temperature of each bath and generates temperature control curves.

7.Real-Time Pressure Curve Monitoring:

Pressure curves from multiple stations can be monitored in real-time on a single interface.

8.Self-Cleaning Electromagnetic Valve:

The valve includes self-cleaning functions for easier maintenance.

9.One-Button Pressure Reset:

A simple one-button function allows for quick pressure resetting.

10.Flexible Pressure Units:

Units can be easily switched between MPa, Bar, and PSI, catering to operational requirements in different countries.

11.Leak Detection and Real-Time Monitoring:

The system features leak detection, burst identification, real-time monitoring, power failure protection, constant pressure maintenance, and data preservation during power outages (with a data retention time of 7 days). It also supports data recovery, printing of test results, and storage functionalities.

Pressure Supply Station (Pump Station)

1. High pressure and performance capabilities.

2. Low noise level.

3. Protection system against electrical or water leaks.

4. Built-in filter to prevent scale buildup in the electromagnetic valve and the main device's piping, extending its lifespan.

Technical Parameters:

1. Pipe Diameter Range: 16 mm - 1600 mm.

2. Pressure Control Range: From 0.3 to 10 MPa. Measurement units: MPa, PSI, or Bar.

3. Pressure Control Accuracy: -1% to +2% (default).

4. Pressure Display Resolution: 0.001 MPa, 1 psi, or 0.01 Bar.

5. Permissible Error Margin: Within 0.5% of the display.

6. Installation Time: 0 to 10,000 hours (set in the counter or countdown). Minimum time interval: 1 minute.

7. Pressure Control Modules: 1-6 (5 independent stations for each module).

8. Working Stations: 3-30 units.

9. Stand Dimensions: 650 × 600 × 1800 mm.

10. Pump Station Dimensions: 500 × 550 × 850 mm.

11. Power Supply for Stand: (220-15% to 220+10%) VAC, 50 Hz, 0.5 kW.

12. Power Supply for Pump Station: (380-15% to 380+10%) VAC, 50 Hz, 4.0 kW.

Click to download the complete content