Plastic Pipe Testing Equipment

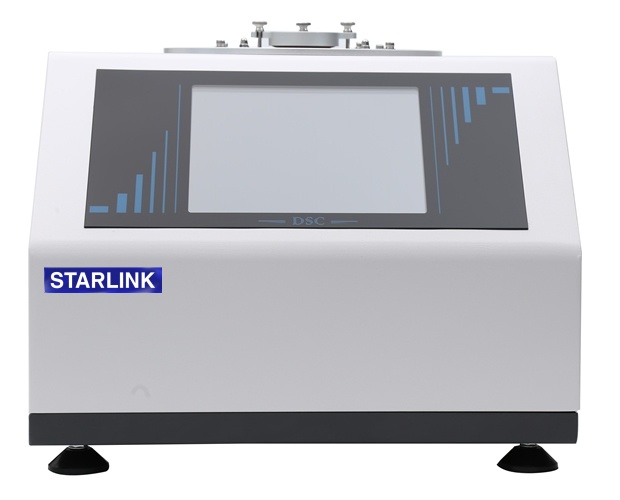

Differential scanning calorimeter

The differential scanning calorimeter is specially used to measure the oxidation induction time (OIT), which indicates the thermal stability, of pipes. This measurement pertains to the thermal stability of PE pipes at a temperature of 200 °C.

Model:SL-DSC510

Standards:

ISO 11357-3 Part 2 : Determination of glass transition temperature and glass transition stepheight.

ISO 11357-3 Part 3 : Determination of temperature and enthalpy of melting and crystallization.

ISO 11357-3 Part 6 : Determination of oxidation induction time(isothermal OIT) and oxidation induction temperature(dynamic OIT).

Features:

1. Industrial-grade 8-inch touch screen, the instrument face frame is perfectly combined with touch screen.

2. The sensor is closely integrated with the furnace body to make the baseline more stable, and the sensitivity and resolution are greatly improved.

3. USB communication interface, strong versatility, reliable and uninterrupted communication, supports self-recovery connection function.

4. Digital flow meter, air flow control is more precise.

5. Automatically switch the two-way atmosphere flow, fast switching speed and short stabilization time. At the same time, a protective gas input is added.

6. The software is simple and easy to operate.

Technical parameters:

1. Temperature range: room temperature~500℃

2. Temperature resolution: 0.01℃

3. Temperature fluctuation: ±0.1℃

4. Temperature repeatability: ±0.1℃

5. Heating rate: 0.1~100℃/min

6. Constant temperature time: recommended <24h

7. Temperature control methods: heating, constant temperature (automatic program control)

8. DSC measuring range: 0~±600mW

9. DSC resolution: 0.01mW

10. DSC sensitivity: 0.01mW

11. Power supply: AC220V/50Hz or customized

12. Atmosphere control gas: nitrogen, oxygen (the instrument automatically switches)

13. Gas flow rate: 0-300mL/min

14. Gas pressure: 0.2MPa

15. Display mode: 8-inch LCD touch screen display, super hardness instrument mask design.