Geotechnical Product Testing Equipment

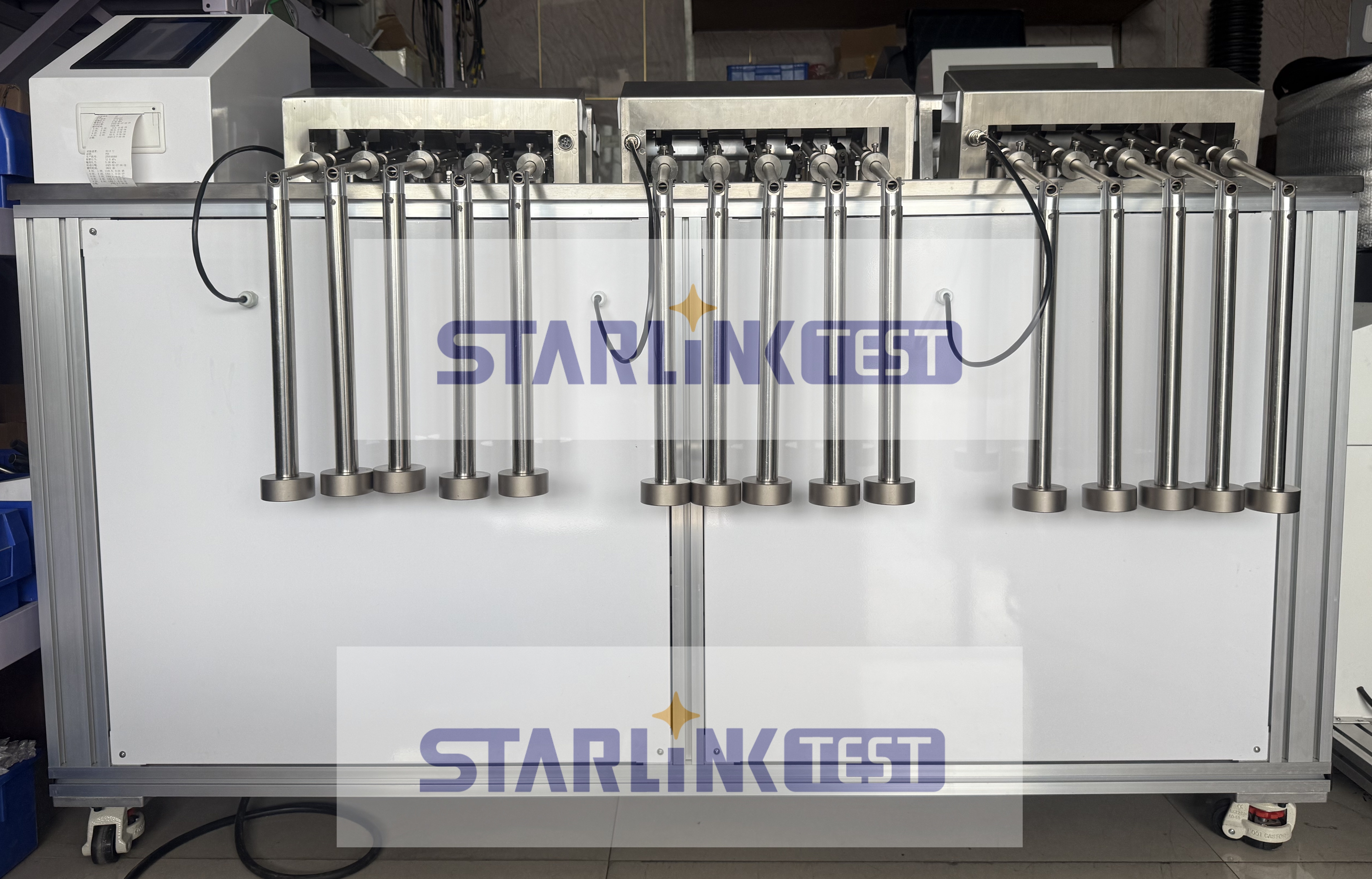

Notch constant tension testing machine

The device is used for the tensile load stress cracking test of geosynthetic membranes (NCTL test). This testing method is employed to develop test data, which can be used to assess the sensitivity of polyolefin geosynthetic membrane materials to stress cracking under constant tensile load conditions and accelerated environmental conditions.

Geosynthetic membrane samples with notches are placed under a constant tensile force in a high-temperature surfactant, where this machine tests and records the sample's fracture time.

Standard: ASTM D5397-20

Device Features:

The inner lining of the medium tank is made of welded corrosion-resistant non-metallic materials. The sample frame is designed with six testing units, each with five positions. All six units can conduct tests independently or simultaneously, ensuring high testing efficiency, ease of operation, and accurate reliability. The temperature field in the bath is uniform, with minimal temperature fluctuations. The 7-inch touchscreen control allows for automatic control of the medium temperature and automatic recording of fracture times. After the test is completed, test data can be printed. It also features an alarm function for abnormal temperature and liquid levels.

Main Parameters:

Number of positions: 20-30 positions available

Temperature range: Room temperature to 80°C

Bath volume: 120L